Denton Silica Free Quartz Countertops News

Low Silica Quartz 2026: The Complete Guide to Q10 vs Q40 Standards

The quartz industry changed composition. Most people in the trade know that. What fewer people can clearly explain is what Q10 and Q40 actually mean, which products hit which threshold, and—the question fabricators keep asking—how much silica reduction is actually enough. What Is Low Silica Quartz? Low silica quartz is engineered stone that has replaced a significant portion of its traditional cry...

Silica-Free Countertop Options 2026: Complete Guide to Engineered Stone + Alternatives

The North American surfacing industry has reached a definitive turning point in 2026, transitioning from a reactive stance on occupational health to a proactive, technology-driven paradigm of total silica management. For designers, architects, fabricators, and distributors, the landscape is no longer defined by the traditional 93% quartz slab, but by a sophisticated array of mineral-based, bio-com...

OSHA Silica Regulations 2026: Your Complete Compliance Guide for Countertop Fabrication

The year 2026 marks a definitive inflection point for the stone fabrication industry in the United States. For decades, the sector has operated under a regulatory framework that was largely reactive, addressing hazards often after the onset of occupational disease. However, the convergence of epidemiological data confirming a silicosis epidemic, the implementation of aggressive National Emphasis P...

Radical Surfaces Changes the Game for Distributors’ Business Model

OK Stone, a US-owned manufacturing company in Texas, will be offering engineered quartz products (Bioquartz and Chromia), the innovative thin-slab technology (Kreos-Plus) for vertical applications, and the strategic advantages of a new business model for distributors. The trade name for the business is Radical Surfaces , and the product line is called Italic . Stage 1: Main Products (Bioquartz and...

Engineered Quartz Cheap Cost – Is More Than You Think

When shopping for countertops, the allure of cheap quartz engineered countertops can be irresistible. Rock-bottom prices promise the same elegant look and durability as premium surfaces, but at a fraction of the cost. However, behind the glossy marketing materials and attractive price tags lies a harsh reality that makes homeowners wonder whether all the “savings” was really worth it. While reputa...

The Great Quartz Shakeup: How 50% Tariffs Are Transforming America's Countertop Industry

A supply chain crisis becomes a manufacturing renaissance opportunity The engineered quartz countertop industry experienced a seismic shift in August 2025 when the United States imposed a crushing 50% tariff on imports from India. For fabricators and homebuilders who have relied on affordable Indian quartz slabs for years, this trade action has created immediate challenges—but also unexpected oppo...

BioQuartz®: A Safer and More Sustainable Alternative to Quartz

What is Bioquartz®?

Bioquartz® is an innovative industrial material that is 100% free of crystalline silica. It is produced by subjecting regular siliceous and feldspar sands, or remnants from the slab manufacturing process, to a pyrolytic transformation, which involves melting these materials at approximately 1500°C. This process creates a material that possesses the same technical and aesthetic features as quartz, making it an ideal substitute in the production of engineered stone slabs [3].One of the key advantages of Bioquartz® is its safety profile.

Crystalline silica, a common component of natural quartz, is a known carcinogen that poses significant health risks to workers involved in the fabrication of quartz surfaces [5]. By eliminating crystalline silica, Bioquartz® provides a safer work environment and reduces the risk of silicosis and other respiratory illnesses[2]. Furthermore, there is a growing policy focus on restricting the trade of products with high crystalline silica content [4]. Bioquartz® offers a solution to comply with these regulations and provides a responsible alternative for manufacturers and consumers concerned about the health and environmental impacts of crystalline silica.

Technological Applications of Bioquartz®

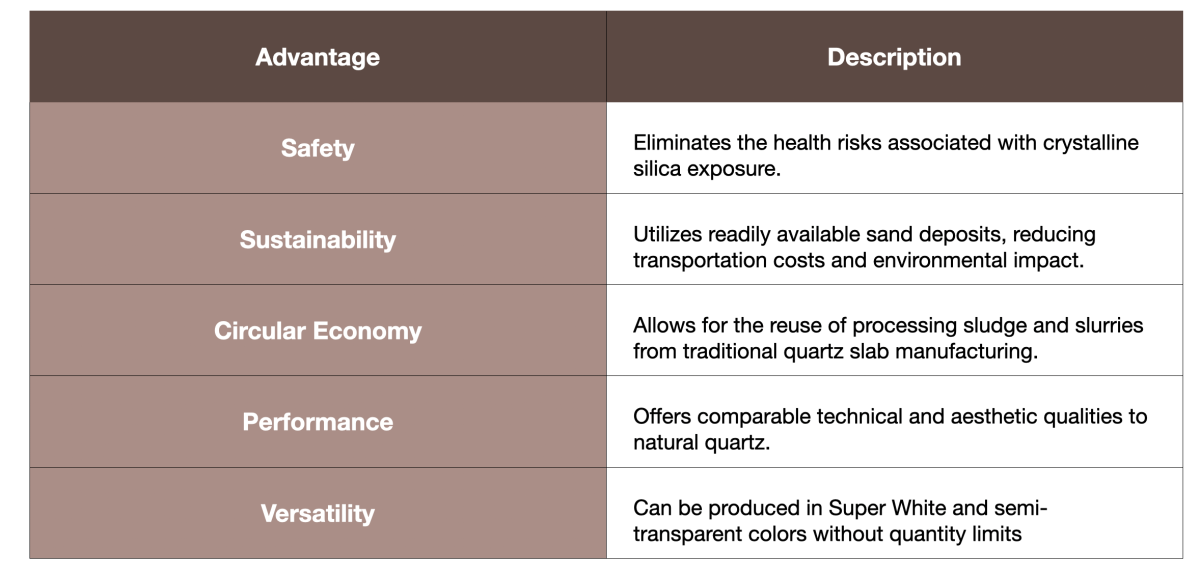

The primary application of Bioquartz® is in the manufacturing of engineered stone slabs. These slabs are widely used in countertops, flooring, wall cladding, and other applications in the construction and interior design industries [2]. Bioquartz® can be used as a direct replacement for quartz in the production process, offering several advantages, which are summarized in the table below:

Advantages of Bioquartz®

In addition to the advantages outlined above, Bioquartz® offers several specific benefits over traditional quartz:

- Enhanced Health and Safety: Bioquartz® is completely free of crystalline silica, eliminating the risk of silicosis and other respiratory illnesses associated with quartz dust exposure. This makes it a safer choice for workers and contributes to a healthier work environment [6].

- Improved Sustainability: Bioquartz® is produced using readily available sand deposits, reducing the need to quarry and transport large quantities of quartz. This reduces transportation costs, minimizes environmental impact, and supports sustainable sourcing practices [6].

- Compatibility with Existing Processes: Bioquartz® can be seamlessly integrated into existing vacuum vibro-compression production processes, making it a convenient and cost-effective alternative for manufacturers [6].

History of Bioquartz® Development

Breton S.p.A., a leading manufacturer of stone processing machinery and technology, has been at the forefront of developing innovative and sustainable solutions for the industry [2]. Over the past decade, Breton and its Institute of Technology (BIT) have prioritized operator safety and waste reduction as strategic goals, leading to the development of Bioquartz®6. This commitment arose in response to the growing concerns surrounding the health risks associated with crystalline silica [4]. Breton has invested significant resources in research and development to create a viable alternative to quartz. They have designed and installed a state-of-the-art industrial plant for the production of Bioquartz®, enabling customers to conduct industrial trials and produce silica-free surfaces [2].

Scientific Research on Bioquartz®

While there is limited scientific research specifically focused on Bioquartz® as a manufactured material, there are studies that explore the formation of quartz in natural settings. For example, research has investigated the precipitation of biogenic quartz (bioquartz) from pore waters that have become supersaturated due to the dissolution of biogenic opal [9]. This research, while not directly related to the industrial production of Bioquartz®, provides valuable insights into the properties and behavior of quartz in different environments.

Environmental Impact of Bioquartz®

Bioquartz® offers several environmental benefits compared to traditional quartz:

- Reduced Transportation: The use of readily available sand deposits reduces the need to transport ground quartz from distant quarries, minimizing transportation costs and associated pollution. This also contributes to a lower carbon footprint and reduced reliance on fossil fuels [2].

- Waste Reduction: The production process allows for the reuse of processing residues from traditional quartz slab manufacturing, contributing to a circular economy and minimizing waste. This reduces the need for landfill space and promotes resource efficiency [7].

- Elimination of Crystalline Silica Dust: Bioquartz® eliminates the generation of crystalline silica dust during the fabrication process, reducing the environmental impact associated with this hazardous material. This protects both workers and the environment from potential harm [5].

Future Developments and Applications

Bioquartz® is a relatively new material, but it has the potential to significantly impact the engineered stone industry and beyond. Future developments may include:

- Wider Adoption: As awareness of the health risks of crystalline silica grows and regulations become stricter, the demand for Bioquartz® is expected to increase, leading to wider adoption in the construction and design sectors.

- New Applications: The unique properties of Bioquartz® may lead to its use in other applications beyond engineered stone, such as ceramics, glass, and other industrial materials. This could further expand the market for Bioquartz® and contribute to its overall sustainability.

- Enhanced Sustainability: Further research and development may focus on optimizing the production process to further reduce the environmental impact of Bioquartz®. This could involve exploring new energy sources, minimizing water consumption, and improving waste management practices.

Bioquartz® represents a significant advancement in the engineered stone industry. By eliminating crystalline silica, it offers a safer and more sustainable alternative to traditional quartz. With its comparable technical and aesthetic qualities, Bioquartz® is poised to become the material of choice for manufacturers and consumers seeking to prioritize health, safety, and environmental responsibility.